New for 2024

"We are very excited to announce that Aircraft Extrusion Company is now stocking distributor for AllSafe products. Design and manufactured in Germany, AllSafe offers a wide range of track fitings complimenting our range of extruded aircraft shapes. For more information please reach out to our sales"

Aircraft Extrusion Co.

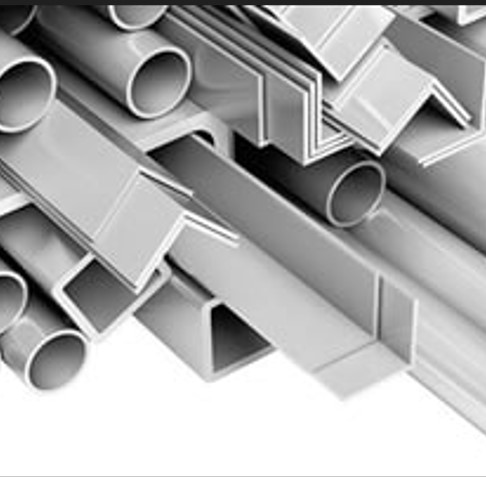

At Aircraft Extrusion Company (AEC) we pride ourselves with the ability to provide not only an extensive range of aerospace aluminum shapes in 2024, 6061 and 7075, but as a vertically intergrated company our capabilities expand beyond material distribution but also include custom shape manufacturing, cnc prototype, seat fittings and aircraft cargo nets.

Read More ...