Operations

Why our rejection rate is so low

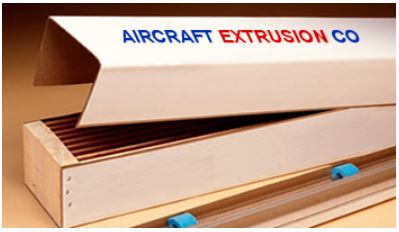

Understanding how companies inspect, pack and ship aerospace profiles is very important. Structural shapes that are transported in flimsy tubes or cardboard are a recipe for disaster and the risk of exposure to damage is high. Aircraft Extrusion Company not only understands this concept, but aggressively addresses the task with a solution to fit all of our customers needs. Our flex form cartons significantly reduce our exposure and mitigate risk of freight damage.

How we inspect

How we pack

We take pride in our extruded shapes and tubes, and the way we pack them. Bad packing is one of the most common area for damage. It benefits no one and everyone loses. All our extrusions are packed in either a sturdy .180" thick tube for short length up to 6ft. Longer pieces are shipped in either our 5" flex-form packaging or our larger 4 x 8 packaging. Flex-form is densely laminated paperboard panels with paper separations allowing the panels to be folded to create a finished product. Flex-form comes in varying dimensions including squares, rectangles, L-shapes, U-shapes, and triangles